- Power Solutions

- Airport Aviation Solutions

- Retail Solutions

- Logistics warehousing

- Medical Drug Solutions

URL:www.abesth.com

TEL:+852-6722 6094

Address:FLAT/RM 109 TOP JADE MANSION NO 608 CANTON ROAD KL

Background:

The Power Measurement Center is an energy measurement and testing institution in the power industry, responsible for the safety lifecycle management of energy measurement instruments within its jurisdiction, including procurement, warehousing, testing, distribution, installation, operation monitoring, and other aspects. With the deepening of urban network renovation and the work of one meter per household for residents, the number of newly installed electricity meters has sharply increased, and the measurement center has applied barcode technology to improve management efficiency. Barcode technology has changed the management of assets in power measurement centers. However, with the development of measurement center business and the urgent need to improve management efficiency, the limitations of barcode technology are becoming increasingly significant. Building a more advanced data collection method and significantly improving warehouse management efficiency is of great significance.

Overview of the plan:

This system is an innovative project that integrates RFID automatic recognition technology, computer software and control technology, and network technology. By physically binding RFID electronic tags to electricity meters, and associating electronic tag information with the identity information of measuring assets through backend data, the electronic tag information is obtained through RFID reading and writing devices at subsequent nodes to achieve identification of measuring asset identity.

System process:

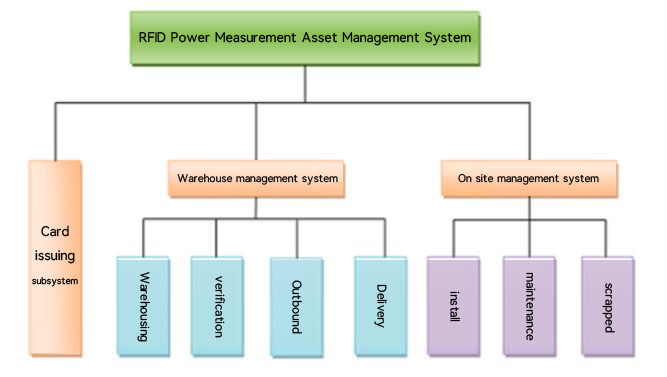

Establish a refined management application system for electricity meter assets based on RFID technology, optimize existing business processes, achieve dynamic logistics management mode, and achieve refined and dynamic management of the entire lifecycle of electricity meters from factory, warehousing, verification, outbound to distribution, installation, operation and maintenance, and scrapping nodes. The system process design is as follows:

The supervisory department assigns designated meter serial numbers based on sales needs. The serial number of the electricity meter is assigned by the competent department to the electronic label supplier. Suppliers print labels and write information based on coding. The printed electronic labels are pasted by the meter manufacturer on the production line. The electricity meters with electronic labels will be delivered to the corresponding power supply bureau warehouse. From this, it entered the RFID warehouse management information system of the power grid company. For meters that require inbound and outbound data collection, RFID devices can be used to collect inbound and outbound data.

When an electric meter with an electronic label is passed through a scanning device, the antenna exchanges bidirectional data with the electronic label through microwave communication, reads relevant information from the electronic label (reading the same information as the existing barcode content), and transmits the data information in real-time to the data center.

- Prev: Airport Aviation Solutions

- Next: