- Power Solutions

- Airport Aviation Solutions

- Retail Solutions

- Logistics warehousing

- Medical Drug Solutions

URL:www.abesth.com

TEL:+852-6722 6094

Address:FLAT/RM 109 TOP JADE MANSION NO 608 CANTON ROAD KL

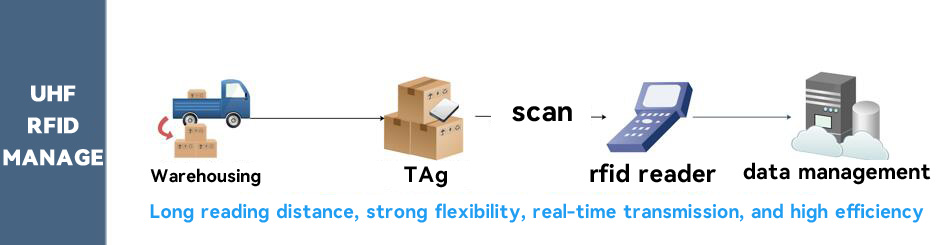

The goal of an intelligent warehouse management system is to establish a fast channel based on RFID technology, achieve warehouse storage statistics, and high-speed automatic recording of incoming and outgoing goods. The system uses RFID middleware as a platform to configure multiple processes such as inbound, inventory, transfer, and outbound.

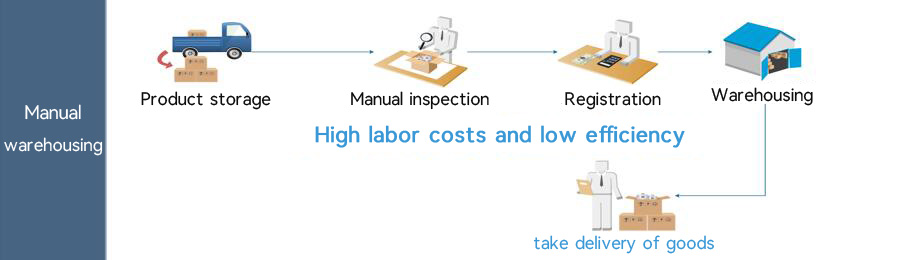

Traditional warehouse management faces challenges

The traditional warehouse management system is still partially stuck in the original manual operation management method, which restricts the level of enterprise warehouse management.

Specifically manifested as:

The drawbacks of traditional warehouse management can be summarized as follows:

1. High labor costs and waste of human resources. Manually handwritten record data and input it into a computer for data collection, statistics, and organization.

2. Low work efficiency. Slow data entry speed and low accuracy.

3. Inaccurate storage data. If there are too many inbound and outbound quantities, the accumulation of documents can easily lead to delayed data or data errors caused by the carelessness of staff.

4. Easy to forge and modify. Due to human factors, stored information is easily modified by humans.

5. The information is not detailed and the location is not clear. The information materials are all records of the entire batch of product information, without detailed records of each product information, and the location is not clear, making it difficult to find.

Overview of the plan:

In the whole warehouse management, the combination of incoming and outgoing goods, inventory statistics, management and UHF RFID technology can efficiently complete various management operations, such as designated stacking areas, shelf picking and replenishment. The UHF RFID warehouse management system can also provide accurate information about inventory conditions, allowing managers to remotely read storage quantities and stored goods information, quickly identifying and correcting inefficient operations, thereby achieving rapid supply and minimizing storage costs. In this way, the accuracy and speed of warehouse management are enhanced, service quality is improved, costs are reduced, labor is saved, and losses, data errors, and delays caused by inventory, import and export errors, etc. in the entire warehouse management are reduced, making it easy for statistics and management; And passive electronic tags have the characteristics of low cost, small size, convenient use, high reliability and lifespan, which assist in warehouse management, improve efficiency, and simplify warehouse management operations.

Business Process:

1. Write product information on the label. Before entering the warehouse, products or other goods that are offline from the production line should be equipped with matching RFID cargo labels based on the characteristics of the goods themselves, and the cargo labels should record the information of the goods. After installing the cargo labels, they will be placed according to the rules and waiting for storage;

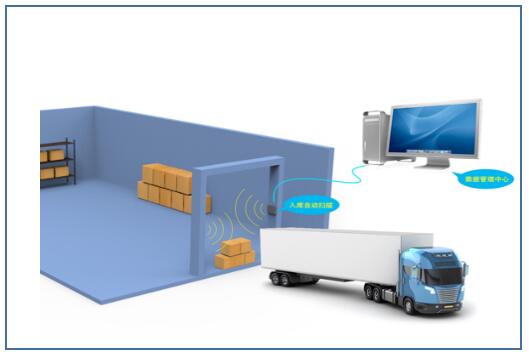

2. Product warehousing. Install RFID channel type reading equipment at the warehouse entrance, complete batch reading of goods label information and upload it to the backend management system during warehousing, and complete batch warehousing of goods;

3. Product classification. After the goods enter the warehouse, they will be classified according to specifications and placed in corresponding types of storage locations. A signboard will be installed for each storage location, and electronic labels will be attached to each signboard, which will serve as warehouse location labels. And give each identification plate a number. The storage location label stores an ID number that uniquely identifies this shelf. Through the staff holding an RFID handheld device, the ID number on the label can be read, and the backend system database can be called to obtain the storage information, including the type, name, model, unit price, production date, shelf life, performance, etc. of the item;

4. Product migration management. During the warehouse transfer operation, the staff holds a handheld RFID handheld device, and the system sends a warehouse transfer instruction to the mobile data collector. The warehouse transfer personnel find the designated storage location, take out the specified quantity of goods from the storage location, and transport the goods to the destination storage location. The goods are sent to the storage location, the content of the shelf label is modified, and the warehouse transfer operation information is sent back to the backend system.

5. Inventory management. When conducting warehouse management operations, reading the tag number can determine whether the current job position is correct. In addition, as long as the ID number of a certain shelf is entered, the relevant information of that ID can be retrieved from the backend database, thereby realizing the material storage function.

6. Goods outbound. The process of goods outbound and inbound is the same, with the same gate for inbound and outbound. RFID reading devices can be reused, and the RFID reading devices scan all the information of goods outbound and upload it in real-time to the backend system to complete the outbound operation of goods.

Another benefit of UHF RFID technology is reducing manpower during inventory counting.

The design of UHF RFID is to automate the registration of goods. UHF RFID has a long reading distance, and the information read is transmitted to the computer and saved. There is no longer a need for manual inspection or scanning of barcodes during inventory, reducing manpower and material resources, making it faster and more accurate, and reducing losses; And the automated warehouse management system has low human factors, high accuracy, and is less prone to falsifying data. The standardized operation requirements for personnel are also relatively low, reducing labor costs and human resource waste.

- Prev: Medical Drug Solutions

- Next: Retail Solutions